Vacuum bagging is a simple and very effective way of removing excess epoxy from the laminates and pressing the laminates together making the layers more densely packed. The end result is a lighter, stronger and truer part. The process involves first covering the wet laminates with a release material and then a batting material on top to absorb the excess resin. The entire part is then wrapped in a plastic, air-tight bag and a vacuum is applied to press evenly on the part. Heat tenting the part and raising the temperature to about 150 degrees with a small heater helps liquefy the resin and facilitates the flow of excess resin thru the release material and into the absorbing layer.

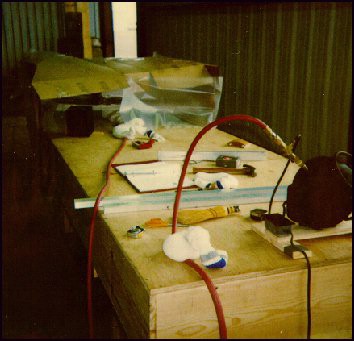

In this picture, the winglet is wrapped in a vacuum bag under a plastic heat tent at the far end of the table. Notice the black object at the near end of the table. This is the improvised vacuum pump Tim and I built for $20 called "The Cheap Little Sucker". It was made out of an old refrigerator compressor, a vacuum gauge, a brass bleeder valve and a couple compression fittings - it worked GREAT! (Remember, the opposite end of a compressor IS a vacuum pump)

Here is a picture of the winglet being removed the next day. Notice the layers of release material, batting, and the plastic bag. Winglet Bag Removal

Back to the Proto-page

Back to the Proto-page