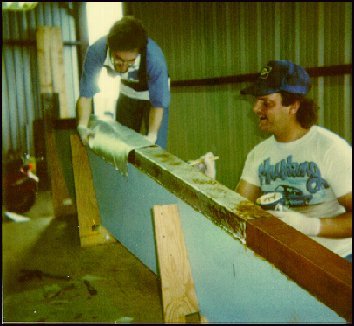

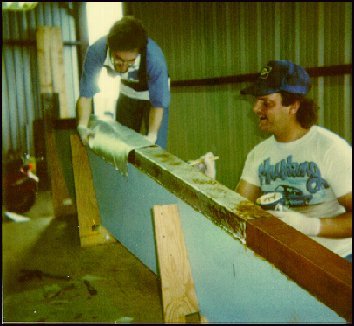

With the leading edges removed, it is now possible to lay-up the shear web plys. They are long runs of uni-directional glass in a +-45-degree orientation. The purpose of the shear web is to connect the two spar caps so that they can share the workload together. When in normal flight, the bottom spar cap is in tension and the upper cap is in compression. Composites are at their best in tension, therefore the shear web allows the cap in compression to be supported by the stronger cap in tension. Confused?...just think about a steel 'I' beam - it's the same principal. Need more help?...build a Berkut! :-)

Once this was cured, the leading edges are re-attached..and, you guessed it...the wing jigs (leading edge section) assure that the leading edges are precisely where they started. The entire wing is then placed upside-down/on its side and prepared for the first wing skin lay-up. I hear that one builder vacuum bagged his shear-web. I think that may be a little extreme given the trouble he had to go through to get everything set up. However, his wings will most likely be ever-so-much lighter. You make the call....

Back to the Proto-page

Back to the Proto-page